Last year I was part of the inaugural sustainable Fellowship training program with @durablemode held @parsons_fashion school of New York. The fellowship training aims to transform and educate sustainability issues in the fashion and beauty industry! This article will cover sustainable fashion training with modeDurable and Eileen Fisher. This project is one of the most eye-opening collaborations I’ve worked on in terms of providing visibility and awareness around a critical issue — sustainability within the fashion industry.

Sustainable fashion is a new movement that allows producing clothes, shoes and accessories in an environmentally and socio-economically sustainable manner.

As a stylist, fashion lover and consumer myself, I wanted to bring some awareness to this topic. As I mentioned above at the fellowship training, I had the opportunity to learn more about this topic and connect with brands that practise this movement. We as consumers need to be more informed and aware of practicing sustainability and I am fully supporting this movement. I realize we all need to bring awareness to this matter.

Today, many sustainable fashion brands produce high-quality, eco-friendly collections. One of them being Eileen Fisher, one of the brands that have practiced sustainable fashion for years.

Eileen Fisher

When it comes to using sustainable and ethical manufacturing techniques, not many people in the fashion industry can compare to womenswear designer, Eileen Fisher, who founded her company 35 years ago and started her take-back program to recycle clothing 10 years ago. I choose Eileen Fisher because I loved learning about the brand at the fellowship training.

Her dedication to the cause of the recycling method, sourcing sustainable fabrics, and fighting unfair labour conditions is remarkable.

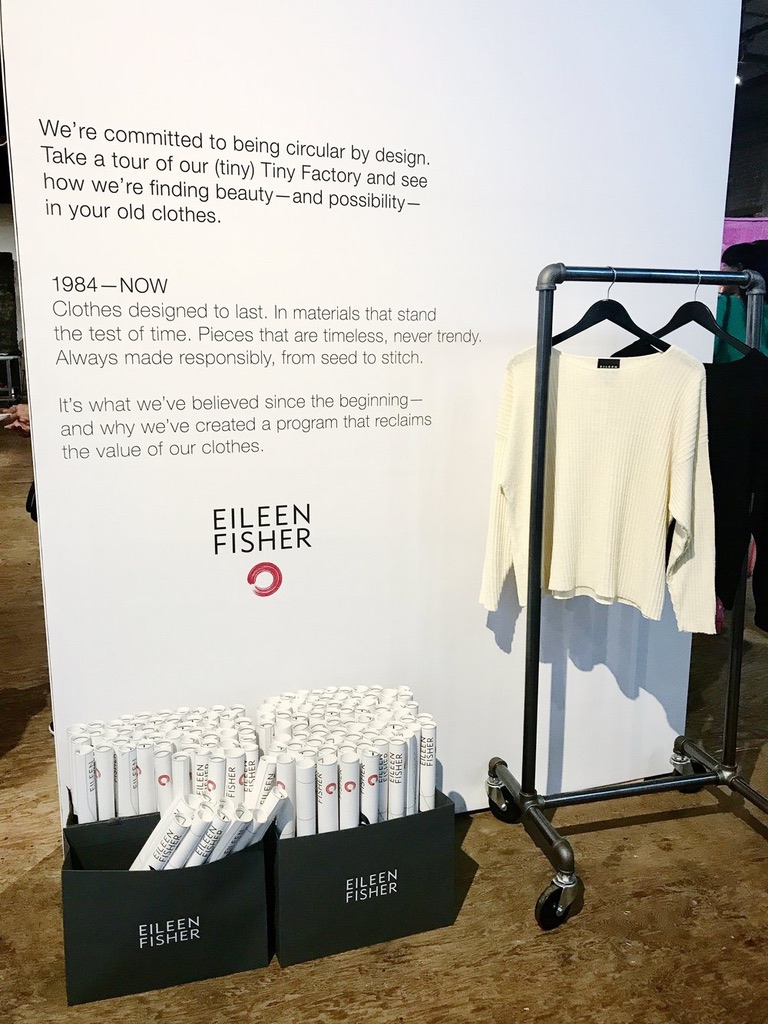

As a pioneer of sustainability, the brand has approached a new circular and zero-waste initiative called “Waste No More” to bring more awareness of sustainability issues within the fashion industry and take responsibility for the clothes that they put out into the world.

Tiny Factory

Eileen Fisher’s Tiny Factory, located in Irvington, New York, was worth the visit. On this blog post, I will take you inside the Tiny Factory facility of Eileen Fisher and show you how old clothes can be worn again.

The tiny factory has developed its own sorting process for returned items.

The idea of the Tiny Factory is that waste can be turned into new clothing. While touring the Tiny Factory, one can’t help but notice where a meticulous sorting and record-keeping process transforms old clothes into something new and beautiful.

The factory is clean and organized, and every step is processed by manual labour.

Upon arriving at the Tiny Factory facility 40 min in the train from New York City, I met Maya Carmosino, the PR + Social Media Coordinator of the brand. I was welcomed by the friendly staff, where they showed me step by step all the process of renewing clothing. Since all of the clothing produced in the Tiny Factory is secondhand, sorting out the garments is the first step once the customers drop the clothes. The sorting is the most crucial part of the whole operation to identify what needs to be done to the garment so that it can be resold. Skilled workers that know the textile well sort the garments into piles based on colour and fabric content. Scroll down to see all the steps

CLEAN – RESTORE – RESALE

Clothing that is in new condition is set aside after washing to be sold through Eileen Fisher’s secondhand program, and garments that are in near-perfect conditions are fixed and sold as-is. The Tiny Factory has its own store on-site, where customers can come shop for secondhand Eileen Fisher pieces at affordable prices. The pre-owned pieces are sold online.

REMANUFACTURING

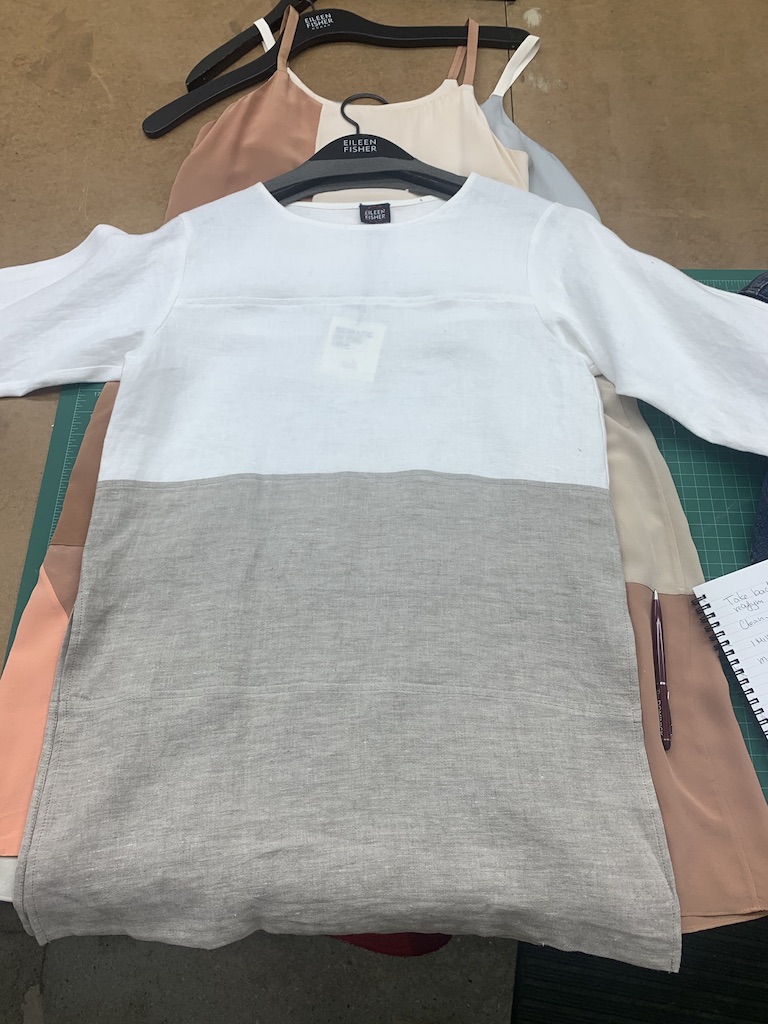

Damaged clothing beyond repair and cannot be fixed or sold as-is is. Clothing are stored in bags sorted by fibre, style and colour. After sorting and washing comes the process of another process. After sorting and cleaning come the process of “laying out.”

Garments are sorted by fabric and colour.

After they decide how much it takes to produce one new pattern after deconstructing the original garment. They lay out all the garments and then cut the reusable pattern and redesigns the new piece. I loved all the pieces they design in the Tiny Factory. Carmen Gama showed me how panelling from multiple pairs of pants come together to make one denim tunic top. As head of the Renew design team, Gama is in communication with designers from Eileen Fisher’s main lines. She looks for ways to recreate new garments, and I think she is very talented. The steps to create every new garment determines how much it will cost Gama explains.

The small scraps of the cutting process are saved rather than tossed, in case the team can find a way to use them. They are all in a box and kept stored in the factory.

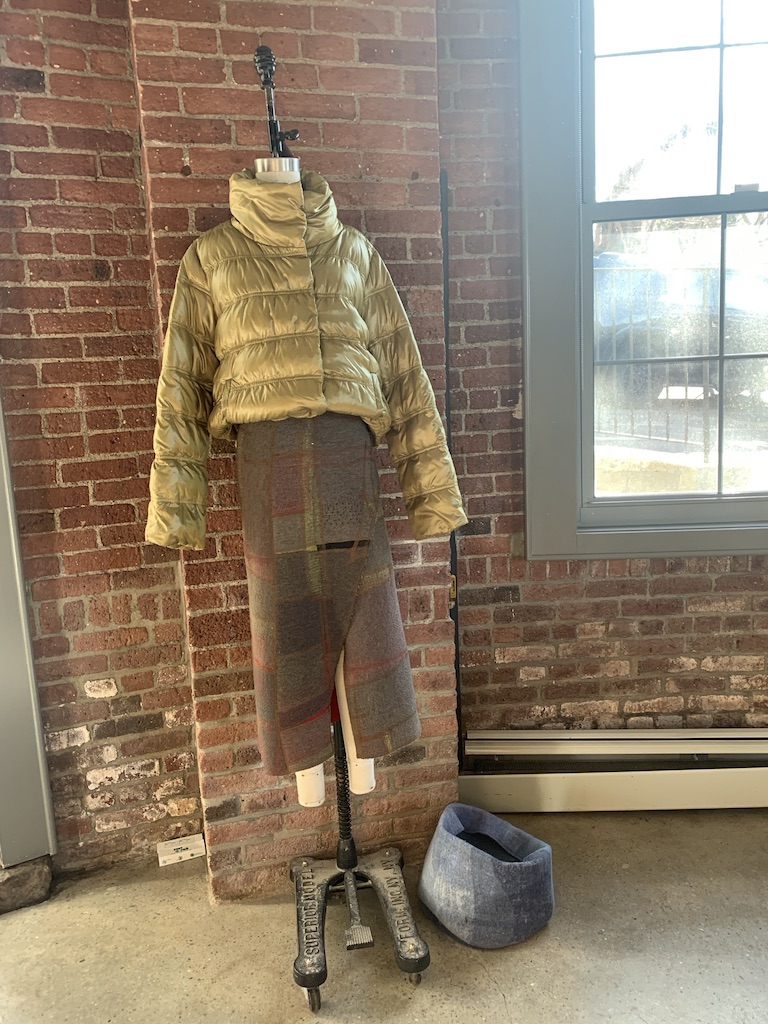

FELTING PROCESS

Felting is another reusable process where they use garments and scraps. It is a process by which fabrics are layered and entered into the felting machine. In addition to creating one-of-a-kind felted coats & skirts (that can cost as high as $2,000), the brand is playing around with creating felted decor, including pillows, rugs and wall hangings and upholstery for furniture. The most mind-blowing process that I have seen. If I didn’t have a chance to see it myself, I wouldn’t believe that from the old denim, you can create such beautiful pieces.

Overall, what the Eileen Fisher team has accomplished at the Tiny Factory is impressive and very admirable. I thank the team for their time and the opportunity to see all the steps in the factory. Also, I want to thank the modeDurable team for having me in their fellowship project. Thank you for reading! Aurela x

Very impressive idea. I love her design. I used to buy clothes 20 years ago when I was in NYC. I still have them..timeless designs.

I will buy more her product to support her great ideas.

Definitely makes closer to 0 waste..